"Reflex vacuum spray tube degassing is recognised as one of the most efficient systems on the market in heating and cooling applications."

Helmut Brinkmann, Product Manager

Advantages

Provide your customers with the very best solution!

- Maximize the energy saving potential of your system

- Assurance of hydraulic balancing and hence the efficient operation of the system

- Reduced corrosion deposits increase operational safety as well as the service life of the system

- Environmentally friendly thanks to a reduction in CO2-emissions

- Compact design as well as easy installation for new and existing systems

- Minimal maintenance

- Satisfied customers

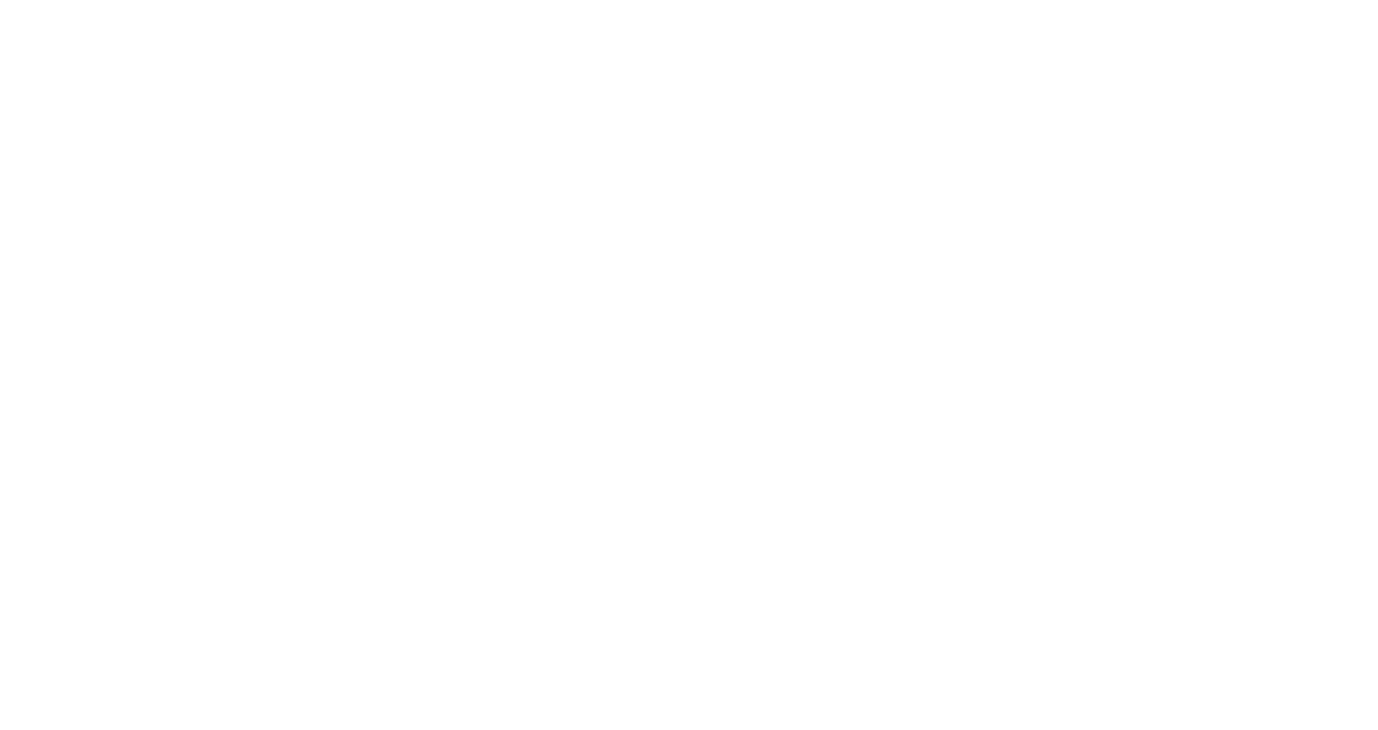

A vacuum spray tube is used to de-gas system water.

- Gas rich system water is sprayed through a nozzle into the spray pipe.

- A pump sucks the water out of the spray tube and pumps it back into the system.

- The configuration ensures that the pump extracts more water from the pipe than can flow in through the nozzle. This creates a vacuum in the spray pipe, which causes the degassing effect.

- If the pump is turned off, water flows into the spray pipe and forces the removed gas outside via air vent

The medium, which is now unsaturated, is able to absorb new gases in the facility system once again, thereby steadily reducing the gas concentration in the entire facility network.

Our tip: the automatic make-up can take place independently via the Reflex Fillcontrol Plus Compact.

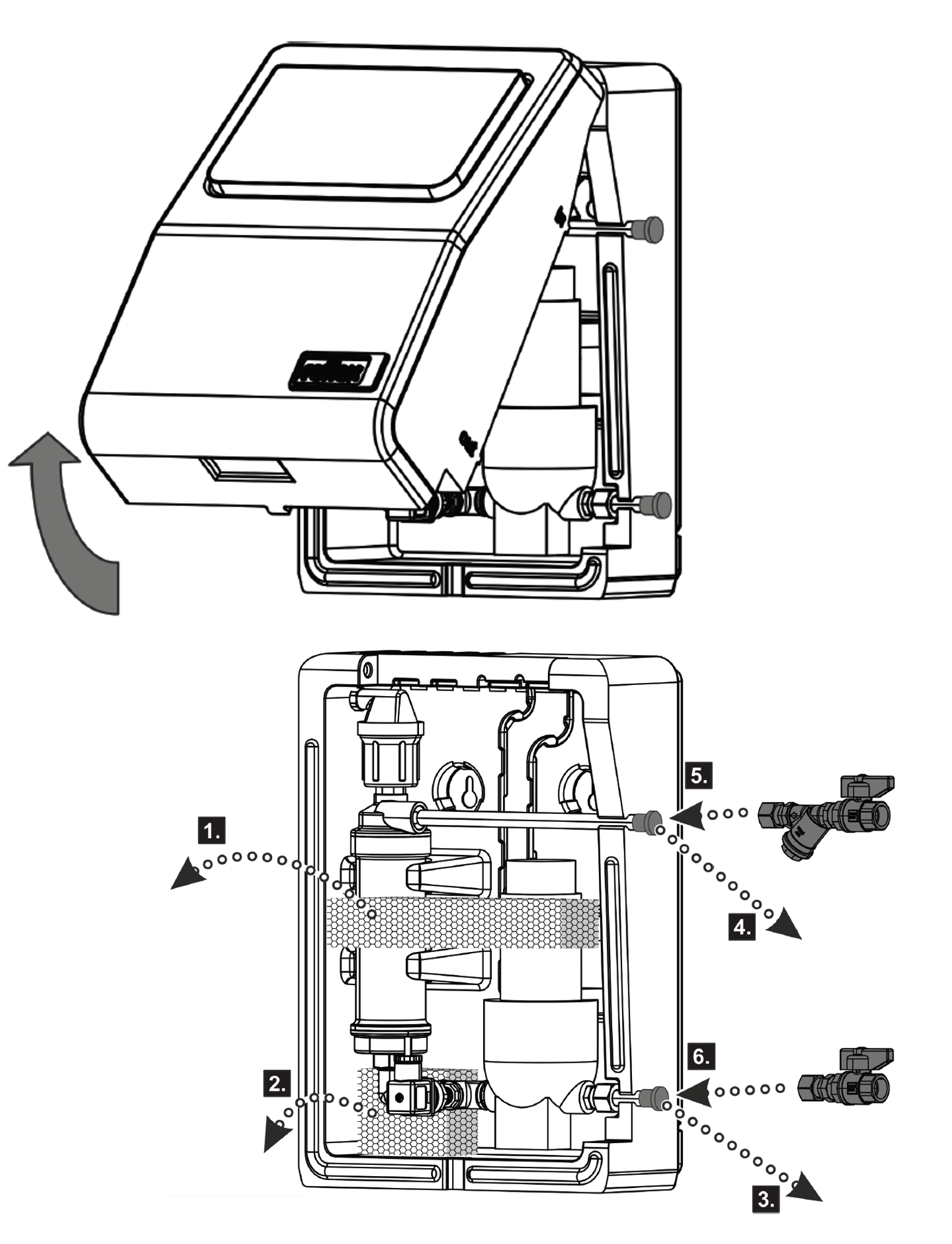

- Mount the pre-installed pipelines onto the device.

- Install the Servitec Mini onto a wall using the holes provided on the rear side of the housing.

- Hydraulic connection: a degassing line to the facility system (high-gas), and a degassing line from the facility system (low-gas), viewed in the direction of flow in the system.

- Open the ball valves of the device.

- Establish a power supply. The device starts in commissioning mode (Auto LED flashes green).

- Press the Auto button, if the LEDs on both buttons are unlit. Continuous degassing starts (4-6 h)

Compact vacuum spray tube degassing with automatic operation

Reflex Servitec, vacuum spray tube degassing for system degassing in closed heating and cooling circuits, configured as a fully automatic multi-function unit with auto-stop operation and automatic hydraulic compensation of the degassing process and monitoring of replenishment.

Functional unit comprising hydraulic part designed for wall mounting and electronic, ergonomically arranged Reflex mini controller unit with CE marking.

Degassing takes place within the hydraulic part using a diaphragm pump in conjunction with a vertically arranged brass vacuum spray tube. This is equipped with a vacuum spray nozzle, dipstick-tube degassing unit and pressure monitoring. The unit as a whole is located in a dirt-protected housing made from expanded polypropylene that can be opened on the front side.

The Reflex Mini control unit is integrated in a robust plastic housing in which both the power and communication electronics and the control panel with dirt-resistant membrane-covered keyboard is housed.

The Reflex Mini control unit is a fully automatic microprocessor control unit with time function, differentiating error and parameter memory, LED display of the operating modes and general error messaging, visualisation of the control states for system pressure and all relevant operating and fault messages.

Control unit completely piped and wired ready for connection according to VDE regulations, mains power cable and mains plug, system connections by means of integrated shut-off valves.

Method of working in optimised operation with cycles for continuous and interval degassing. Actuation takes place via an integrated system pressure interpretation unit with automatic interruption and fault messaging upon exceeding of the running time and/or the number of cycles. Documentation and control of the entire system in respect of the above mentioned parameters.

Technical Features

Max. operating pressure 4 bar

Operating pressure 0.5 to 2.5 bar

Max. operating temperature: 60°C

Max. ambient temperature: 0 to 40°C

Power supply : 230V/ 50Hz

Electr. power consumption: 0.06 kW

Nominal current: < 0.3 A

Connections: G ½

System volume VA: 1 m³

Depth x width x height (mm): 220/295/420

Weight (kg): 5.6

Scope of application

- One- and two-family houses

- Plant systems with low water content

- Extremely simple and cost-effective plug and play system to optimize primary circulation upstream of heat generators using heat exchangers

- Decentralised degassing system for problematic circuits

- Commissioning of panel heating and cooling system as an innovative replacement for costly rinsing at high pressure to remove air and gas pockets

Downloads

Documents

Brochures & flyer

- Sales flyer: containing all essential information on the Servitec Mini.

- Energy efficiency brochure: background information on Reflex energy-efficient solutions

Texts & images

You can purchase the Servitec Mini at your wholesaler or contact the Reflex sales team in your country.

Yes, the Reflex Servitec product range offers solutions for systems of every size and complexity. Special systems are also manufactured for bespoke customer requirements. Find out all about the Servitec product range here.

Make-up takes place either manually (the Servitec Mini indicates when make-up is required), or automatically with the Reflex Fillcontrol Plus Compact

Any further questions?

Contact us directly!

Central hotline

tel.: +49 2382 7069-0 (Mo-Fr 8.00 - 16.30 Uhr)

Technical hotline

tel.: +49 2382 7069-9546 (Mo-Fr 8.00 - 16.30 Uhr)

Contact in your country:

Reflex UK

Tim Williams

Tel. +44 (0)161 266 1043

For other regions click here.

![[Translate to English:] Icon Zertifikat [Translate to English:] Icon Zertifikat](/fileadmin/user_upload/Zertifiziert_1.png)

![[Translate to English:] Bild Servitec [Translate to English:] Bild Servitec](/fileadmin/user_upload/weltweit.jpg)